Cellular

manufacturing is a manufacturing process that

produces families of parts within a single line or cell of machines operated by

machinists who work only within the line or cell. A cell is a small scale,

clearly-defined production unit within a larger factory. This unit has complete

responsibility for producing a family of like parts or a product. All necessary

machines and manpower are contained within this cell, thus giving it a degree

of operational autonomy. Each worker is expected to have mastered a full range

of operating skills required by his or her cell. Therefore, systematic job

rotation and training are necessary conditions for effective cell development.

Complete worker training is needed to ensure that flexible worker assignments

can be fulfilled.

Cellular manufacturing is a hybrid

system that links the advantages of a job shop with the product layout of the continuous

flow line. The cell design provides for quick and efficient flow, and the high

productivity associated with assembly lines. However, it also provides the

flexibility of the job shop, allowing both similar and diverse products to be

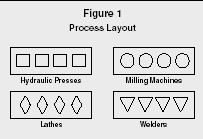

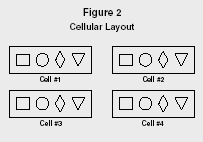

added to the line without slowing the process. Figures 1 and 2 compares a cellular layout to that of the typical

job shop (process layout).

Figure 1 Process Layout

Figure 2 Cellular Layout

Benefits of Cellular Layout

Many firms utilizing cellular

manufacturing have reported near immediate improvements in performance, with

only relatively minor adverse effects. Cited improvements which seem to have

occurred fairly quickly include reductions in work-in-process, finished goods,

lead time, late orders, scrap, direct labor, and workspace.

In particular, production and

quality control is enhanced. By breaking the factory into small, homogeneous

and cohesive productive units, production and quality control is made easier.

Cells that are not performing according to volume and quality targets can be

easily isolated, since the parts/products affected can be traced to a single

cell. Also, because the productive units are small, the search for the root of

problems is made easier.

Below table compares cellular and

functional layouts along 13 key dimensions. It is typical of the improvements

possible with this approach. Cells negate many of the tradeoffs of conventional

manufacturing approaches.

|

Key Element

|

Functional

|

Cellular

|

|

Inter-department Moves

|

Many

|

Few

|

|

Travel Distance

|

500'-4000'

|

100'-400'

|

|

Route Structure

|

Variable

|

Fixed

|

|

Queues

|

12-30

|

3-5

|

|

Throughput Time

|

Weeks

|

Hours

|

|

Response Time

|

Weeks

|

Hours

|

|

Inventory Turns

|

3-10

|

15-60

|

|

Supervision

|

Difficult

|

Easy

|

|

Teamwork

|

Inhibits

|

Enhances

|

|

Quality Feedback

|

Days

|

Minutes

|

|

Skill Range

|

Narrow

|

Broad

|

|

Scheduling

|

Complex

|

Simple

|

|

Equipment Utilization

|

85%-95%

|

70%-80%

|

An

Example

A firm that assembles air-handling products faced high inventories and

erratic delivery. They originally assembled units on a traditional line. Long

setups and logistics required long production runs. Often, they pulled products

from finished goods and rebuilt them for custom orders.

We built twelve small (1-3 person) assembly workcells

that were always set up and ready. People worked in different cells each day

and assembled to customer order. Finished Goods Inventory dropped by 96%.

Lead-time was 24 hours. Productivity improved by 20%-30%.